GT TECH High Toughness Original Structure Layer in situ Cold Regeneration Technology and Application

Time:

2024-08-19

Source:

Introduction

Due to the increase in traffic volume and environmental impact, the structural performance of asphalt pavement shows a declining trend. The design life of conventional asphalt pavement structures usually ranges from 10-15 years. The structural maintenance caused by expiration has problems such as complex process, high energy consumption, high resource demand, and large traffic interference, which greatly restrict travel and economic development. Road construction and maintenance face enormous environmental and resource challenges. In order to achieve the "dual carbon" goal, it is imperative to promote green and low-carbon road maintenance. However, asphalt cold recycling technology combines the advantages of resource recycling and low-temperature construction, which can achieve energy conservation, emission reduction, resource conservation, and sustainable development. It is one of the effective green and low-carbon pavement construction technologies.

1. Defects of traditional cold recycling technology

Traditional cold recycling technology is limited in its road performance and engineering applications due to issues such as insufficient material properties and slow early strength formation. On the one hand, traditional cold recycling technology limits the durability of recycled road surfaces due to the insufficient performance of newly added binders, poor bonding ability and anti stripping performance between old materials. For example, the cold recycling technology using foam asphalt as binder is more prone to loose and peeling than the cold recycling technology using emulsified asphalt as binder, because foam asphalt is bonded to the old material surface in a "point-to-point" manner. On the other hand, traditional cold recycling technology often adds cement to promote the early strength of the mixture, but the hydration process of cement is disturbed by asphalt emulsification and requires a period of time. The curing time of recycled pavement is generally as long as 3-7 days, which will greatly affect the construction progress and traffic opening. At the same time, high cement content reduces the fatigue resistance and toughness of recycled mixtures, limiting the application of the original layer of the recycled layer; In engineering, it is often necessary to add a 5-10cm new asphalt structural layer on top of the recycled layer to restore the strength of the road surface structure, which not only causes resource waste but also often limits its use due to road elevation restrictions.

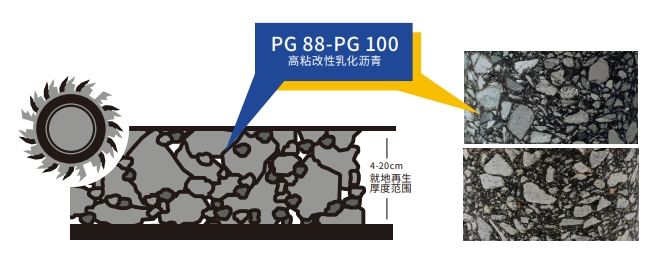

Based on the shortcomings and deficiencies of traditional cold regeneration technology, Huayun Tongda has developed GT TECH High Toughness Original Structure Layer in situ Cold Regeneration Technology. This technology uses independently developed high viscosity modified emulsified asphalt (PG88, 94, and 100 grades) as the binder, and adopts advanced on-site cold recycling units with a single layer implementation thickness of 4-20cm. It solves the problems of insufficient material performance and slow early strength formation of traditional cold recycling technology mixtures, and can achieve on-site cold recycling of the original structural layer of asphalt surface layer and semi-rigid base layer. After forming, the recycled layer has crack resistance, impermeability, and anti rutting performance far exceeding the original structural layer, providing a new solution for restoring and improving the mechanical properties of the original pavement structure without changing the elevation.

2. Advantages of GT TECH High Toughness Original Structure Layer in situ Cold Regeneration Technology

Figure | GT TECH High Toughness OriginalStructure Layer in situ Cold Regeneration Technology

Good durability and long service life

GT TECH High Toughness Original Structure Layer in situ Cold Regeneration Technology uses high-performance polymer modified emulsified asphalt with PG88 and above grades as the binder. The performance of the regenerated mixture exceeds the requirements of PG76 new hot mix asphalt concrete indicators, significantly improving the various properties of the mixture, including fatigue life, ultimate bending tensile strain, fracture toughness, and dynamic stability, effectively resisting the expansion and extension of cracks in the lower bearing layer, and comprehensively improving road performance. The addition of organic specific early strength agents has replaced the addition of cement, which not only eliminates the damage caused by the use of inorganic materials such as cement to recycled mixtures, but also greatly improves the later strength of cold recycled materials. It is possible to extend the lifespan of the regenerated pavement structure beyond 15 years.

Resource conservation and environmental friendliness

Compared to traditional hot recycling processes, GT TECH High Toughness Original Structure Layer in situ Cold Regeneration Technology achieves 100% high-value recycling of recycled asphalt pavement materials, while reducing the amount of binder by 50%; All production and construction processes can be completed at room temperature, achieving the recycling and repair of road surfaces at room temperature. Compared with traditional newly-built hot mix asphalt pavements, it can reduce carbon emissions by up to 90%, making it the most carbon efficient structural maintenance solution currently available.

High regeneration efficiency and minimal traffic interference

Within the same curing time, the strength of in-situ recycled mixture can reach 1.5-2 times that of conventional cold recycled mixture, and traffic can usually be opened 0.5-2 hours after construction is completed.

In situ regeneration, without affecting the elevation of the road surface

Advanced regeneration units are used to sequentially complete processes such as milling, spraying, mixing, paving, and rolling. The depth range of single-layer regeneration is 4-20cm, accurately achieving the regeneration of the original structural layer without the need for additional pavement structural layers and without affecting the original pavement elevation.

3. Application scope and prospects

GT TECH High Toughness Original Structure Layer in situ Cold Regeneration Technology is suitable for structural repair of asphalt surface layers and semi-rigid base layers of various grades of highways, urban and rural roads, effectively solving road surface diseases such as aging, roughness, looseness, rutting and various cracks.

Different types of products can be differentiated based on road grade, operating conditions, traffic volume, and economic requirements.

| Cover Type | Application |

|

PG88 |

Light traffic volume.Structural repair of asphalt surface layer with typical cracking and aging characteristics and structural repair of semi-rigid base layer. |

|

PG94 |

Medium traffic volume.Structural repair of asphalt surface layerwith dense cracks and severe pavement deformation andstructural repair of semi-rigid base layer. |

| PG100 | Structural repair of asphalt surface layer and semi-rigid base layerfor various types of roads with heavy traffic volume and above. |

Note: ① Determine the regeneration depth based on the degree of original pavement diseases and the goal of restoring pavement structural performance; ② 3、 Fourth-class highway, urban secondary trunk roads, branch roads, and rural roads can be directly used as the surface layer after the implementation of high toughness cold recycling. For sections with special requirements for functional recovery such as surface structure and noise reduction performance, it is advisable to add high toughness ultra-thin asphalt wearing course.

4. Application Cases

Previously, GT TECH High Toughness Original Structure Layer in situ Cold Regeneration Technology has been applied for the first time in the Mingxi Village mouth section of Provincial Road S387 (Ebu Pingshan) in the Shenzhen Shantou Cooperation Zone. This is also the world's first successful in-situ cold regeneration project for high toughness road structures.

Image | GT TECH High Toughness Original Structure Layer in situ Cold Regeneration Technology implemented in the Shenzhen Shantou Cooperation Zone

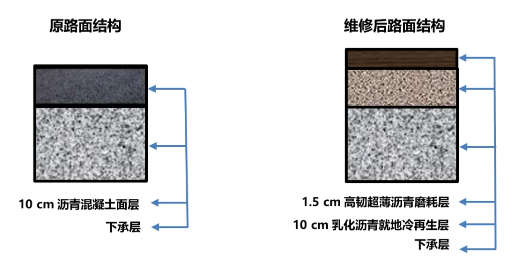

The original road surface of the project was a 10cm asphalt concrete surface layer, which had structural damage problems after long-term use. Based on the actual situation of the original road surface, a high-performance recycling unit was used to mill and plane the road surface. PG94 high viscosity modified emulsified asphalt was used as the binder, and no new aggregates were added during the process, achieving efficient in-situ repair of the road surface structure. After the recycling construction, traffic was quickly opened up. Subsequently, a 1.5cm GT TECH high toughness ultra-thin asphalt wear layer was synchronously laid to comprehensively improve the surface functionality of the road.

Figure | Renovation Plan for the Experimental Section of Shenshan Special Cooperation Zone

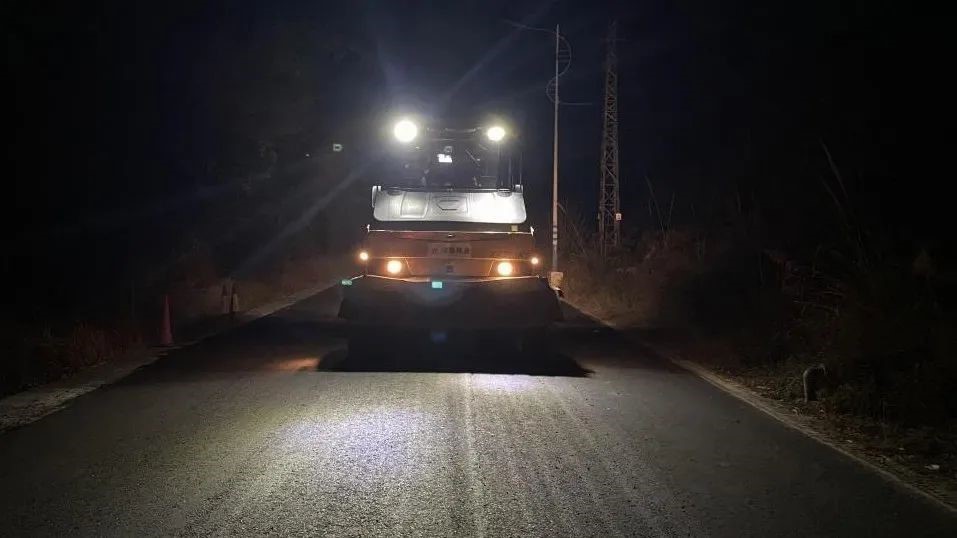

Figure | Rolling of in-situ cold regeneration technology section for GT TECH high toughness original structure layer

Figure | GT TECH high toughness ultra-thin asphalt wear layer implements road surface improvement function

GT TECH High Toughness Original Structure Layer in situ Cold Regeneration Technology has been implemented in the Shenzhen Shantou Special Cooperation Zone, achieving efficient repair of road structures through in-situ regeneration. The recycling rate of old asphalt pavement materials has reached 100%, while greatly reducing the impact of the construction process on traffic operations, effectively improving road driving comfort and safety. The smooth implementation of this project marks Huayun Tongda's leading innovation in key technologies for the regeneration of original layer structures in the field of road structural repair. It will also provide efficient, high-quality, green, and low-carbon new solutions for the national road construction and maintenance industry.